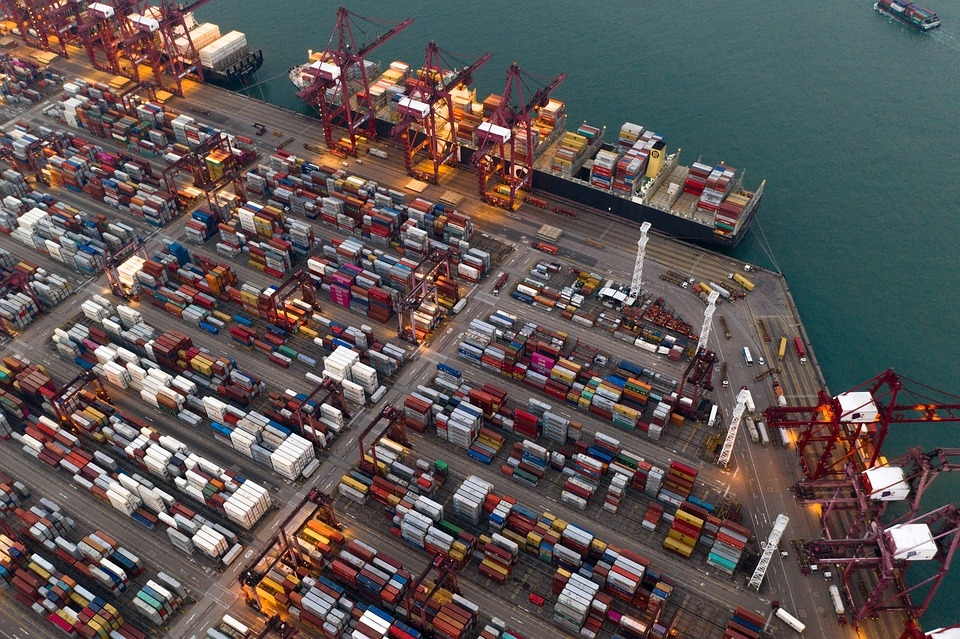

India is all set to transform its sea ports into “smart ports” and in due course upgrade these to ‘intelligent ports’. In this pursuit, Industry 4.0 technologies such as artificial intelligence and machine learning would be put to use, and smart traffic management tools would not only ‘simplify and smoothen the operations of major ports’ but add to efficiency. All this is envisioned in the Maritime India Vision-2030.

Meanwhile, during the three-day brainstorming or “Chintan Baithak”, Mansukh Mandaviya, Minister of Ports, Shipping and Waterways, expressed ‘optimism, dedication and motivation to put India on the world map as the maritime leader’.

There is a worldwide drive to digitalize ports and the global market for ‘smart port’ segment is projected to be US$ 5.3 billion by 2024 from an estimated US$ 1.7 billion in 2019, at a CAGR of 25 per cent. Industry experts have cautioned that “smart ports are the only ports that will survive.”

The International Association of Ports and Harbors (IAPH), a leading organizations in the shipping industry, too has observed that some port administrations have already introduced Industry 4.0 technologies and transforming their ports into ‘smart ports’; while many others “have barely grasped the essentials of digitalization and continue to struggle with a larger reliance on personal interaction and paper-based transactions as the norms for shipboard, ship-port interface and port-hinterland based exchanges”.

Some seaports in Asia, Europe and the US are already using Industry 4.0 technologies in their daily operations. In Asia, China is perhaps the leading nation to have integrated Industry 4.0 technologies. In 2017, Port of Qingdao in China was chosen to be developed into a ‘Smart Port’. Ericsson and China Unicom, a mobile service provider, were tasked to develop 5G network for a fully-automated harbour. This initiative was expected to reduce labour costs by up to 70 per cent.

One of the major highlights of the upgrade was that an automated ship-to-shore (STS) crane operated from the control centre successfully lifted a container by using 5G connection. This 5G smart port solution is being replicated in many other Chinese ports.

China is also building smart ships. In 2020, China announced steel cutting for its first autonomous containership named Zhi Fei to be constructed at Qingdao shipyard. This 5,000 tons vessel can carry up to 300 TEUs and is being fitted with intelligent navigation systems. It would have electric propulsion which would reduce noise and its advanced systems will lessen NOx, SOx and CO2 gasses.

The Indian Ministry of Ports, Shipping and Waterways has given priority to data related initiative in the port sector both at the organisational and operations levels to enhance ‘Ease of Doing Business’. Some of the initiatives include: Direct Port Delivery (DPD); Direct Port Entry (DPE); RFID, and installation of scanners/container scanners which have reduced congestions at the entry gates of the ports. The upgraded Port Community System (PCS 1x version) has been set up in all ports and “enables seamless data flow between the various stakeholders through common interface” which would result in “complete paperless regime, E-DO (Electronic Delivery Order) through PCS made mandatory along with e-invoicing and e-payment.”

The Jawaharlal Nehru Port Trust (JNPT) ranks 32nd among the top 50 ports in the world. The port has been improving efficiency through innovations and reforms. It is using digital technologies for automated management of cargo movements, and vessel-port-vehicle traffic management through data-based analytics. It also uses GPS and image-recognition technologies.

Similarly, there is a push towards “AI-led restructuring of the ports-logistics sector” and a good example is the Nhava-Shewa and Bhiwandi, e-commerce led logistics which has transformed warehouse and trucking operations in the sector adding to efficiency.

Among the private port operators, Adani Ports and Special Economic Zone Limited (APSEZ) merits mention. Its 10 terminals handle 100 million tonnes of cargo annually and the container processing involves AI-based Container Number Recognition System which removes human intervention. This has reduced the need for 45 office workers employed across 15 gates for manual verification and tracking.

The above developments are good examples for many other Indian ports who will have to necessarily adapt to the ongoing transformation in port ecosystem that is rapidly absorbing Industry 4.0 technologies to enable them to remain competitive at national and international levels.

As far as ‘smart ship’ construction is concerned, Cochin Shipyard Limited has taken lead in India to build autonomous vessels and is therefore primed to build ‘smart tugs and ferries’. This should trigger interest among Indian technology and product developers to explore Industry 4.0 technologies for national Inland Water Transport network.

The human resource, that is workers, labour, truckers and supply chain managers will also have to be part of the port-digital ecosystem. Sector-specific talent development is imperative for a number of white and blue-collar jobs. Similarly, vocational institutions are critical for promoting, training and skilling workers with Industry 4.0 tool kits to support Smart port and Smart ship operations.

(Dr. Vijay Sakhuja is former Director of National Maritime Foundation, New Delhi)